The Beer Ticker: Industry News & Notes, New Year Edition

From an icon going hazy to resealable beer cans, here are some recent news and announcements from around the industry.

Showing 281-300 of 837 articles

From an icon going hazy to resealable beer cans, here are some recent news and announcements from around the industry.

Barring a dramatic shift in the forecast, independent breweries should be planning for a future of low—or even no—sales growth. The safest path forward includes reducing risk, optimizing cash flow, and focusing on profitability.

After three early years of explosive growth for Revision, the pandemic combined with leadership changes to slow the company’s roll. Yet Revision made it through—and the Nevada brewery has never been better prepared for the future.

The Lost Abbey and Port Brewing cofounder Tomme Arthur explains what it means to “grow down” for the long haul amid an increasingly competitive landscape for American brewers.

Hop harvest in the Southern Hemisphere begins in March. In the first of two reports on what’s new with hops Down Under, we zoom in on the recent dynamism in New Zealand hop-growing.

While seasonals can struggle to stand out in chain retail, they tend to shine brighter at bars and restaurants.

It may be one of the lowest-selling styles in American craft beer, but some breweries are packing their taprooms by cutting down the menu and serving stange after stange of nothing but Kölsch.

No brewery is too small or too short-handed to get a sensory panel going, and the education and expertise gained can be invaluable to the business. Here’s how to get your panel off the ground.

Some brewers make a strong argument for wider, shallower fermentors—for better esters, healthier yeast, quicker turnaround, and more.

For the third and final installment in our You’ve Got Mail series, our own COO offers his best advice on building newsletters that attract and keep an audience of customers.

Could koji malt open new doors to flavor for creative brewers? Some researchers and a few breweries already are tinkering with the versatile molds responsible for sake, shōchū, and more.

From Bay Area shuffles to free snacks for life, here are some news and announcements from around the industry.

Old hops have never been fresher. With prices on the rise and some hop varieties likely to be scarce, there are treasures to be found in previous crop years. Here we delve into the science of hop storage.

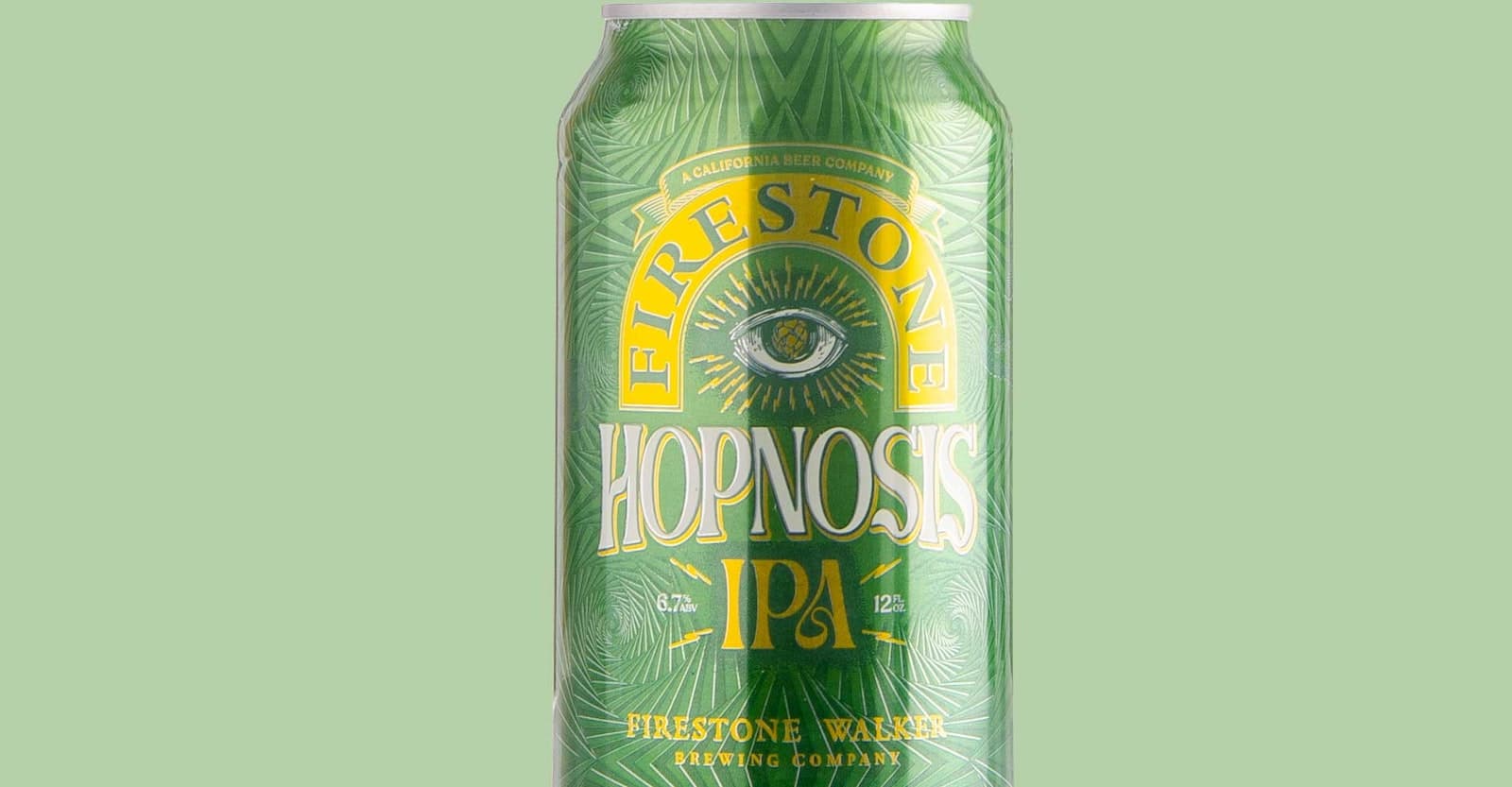

A recent release at California’s Firestone Walker may be a window into where IPA is headed, going for clarity and lean fermentation while borrowing hop-saturation hocus-pocus from the hazy grimoire. Brewmaster Matt Brynildson explains.

The sea of beer variety has flipped the appeal of seasonal beers on its head—but they can still sell well. Here’s some insight on how to capitalize.

From Jackson Hole acquisitions to cross-border collabs, here are some recent news and announcements from around the industry.

The Pennsylvania brewery’s customer long-running newsletter boasts 60,000 subscribers—and growing—with an enviable open rate. In this second of a two-part series, we zoom in on how Tröegs got there.

From growing down to Rising Hope, here are some recent news and announcements from around the industry.

What is open fermentation, and why do some brewing businesses—both traditional and modern—swear by it? Here we take the lid off this method and consider its unique set of strengths and drawbacks.

Where are your hops grown? To put the hop-growing regions in their global context, here’s a comparative look at the production in various countries.