Closing the Loop: Recovering CO2 in the Craft Brewery

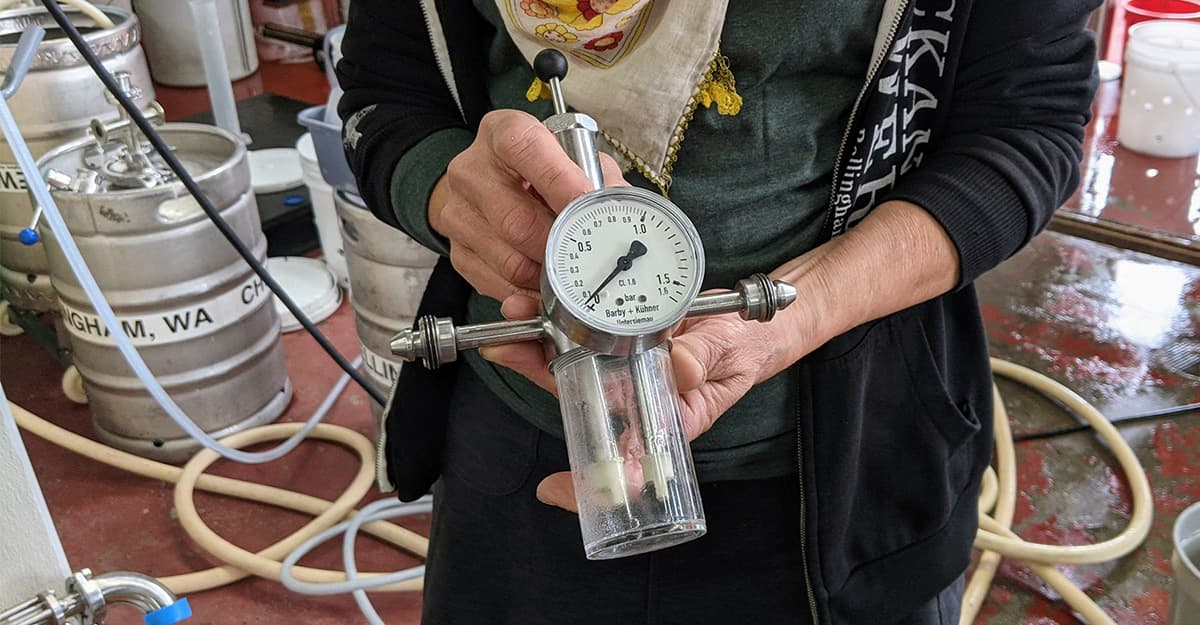

ALL ACCESSOnce the purview of large-scale production plants, recovering the carbon dioxide produced during fermentation is increasingly viable for smaller craft breweries—and it’s increasingly popular, too.